Product Description

Laser Decontaminator

The Laser Decontaminator represents a breakthrough in surface preparation and maintenance technology, utilizing state-of-the-art pulsed laser systems to deliver unparalleled precision, sustainability, and operational efficiency. Engineered for demanding industrial and specialized applications, this advanced system effectively removes a wide range of surface contaminants-including rust, paint, oxides, oil residues, and coatings-while preserving the integrity of the underlying substrate.

Unlike traditional methods such as abrasive blasting, chemical stripping, or mechanical grinding, the Laser Decontaminator operates without generating secondary waste, toxic byproducts, or surface damage, making it an eco-friendly and cost-effective solution. Its non-contact, programmable cleaning process ensures consistent results across various materials, from metals and composites to delicate historical artifacts.

With minimal maintenance requirements, reduced operational downtime, and enhanced worker safety, this innovative technology sets a new standard for high-performance surface treatment in industries such as aerospace, automotive, maritime, and heritage conservation.

Basic Info

|

Model NO. |

LCP-A-500W |

|

Average laser power |

500W |

|

Laser Center wavelength |

1064nm |

|

Scan Range |

5MM-150mm(adjustable) |

|

Cooling Method |

water cooling + Cabinet air conditioner cooling |

|

Supply Voltage/Frequency |

AC220V±10%/50Hz |

|

Power Consumption@25ºC |

<6000W @ LCP-A-500W |

|

Supply Air Pressure |

0.6MPa Remove water and oil to clean compressed air |

|

Chassis Size |

L800mmxW680mmxH1000mm |

|

Weight |

210kg |

Core Technology

The Laser Decontaminator employs advanced pulsed laser technology at its core, utilizing precisely calibrated high-energy beams that emit nanosecond to picosecond light pulses. These ultra-short, high-intensity bursts create an instantaneous photothermal effect where surface contaminants absorb the laser energy and undergo rapid thermal decomposition. The process works through three simultaneous mechanisms:Instantaneous vaporization of surface layers;Plasma-induced shockwave detachment;Photoacoustic removal of microscopic particles.

Advantages

- High Efficiency: The continuous operation mode allows for rapid cleaning of large-area surfaces, significantly improving work efficiency. It can handle a large number of workpieces in a short time, meeting the requirements of mass production.

- High Precision: The laser beam can be accurately focused on a very small spot, enabling precise control of the cleaning area. This makes it suitable for cleaning delicate and high-precision components without causing damage to the surrounding areas.

- Non-Contact Cleaning: Since it cleans without physical contact with the object, there is no risk of mechanical damage or scratches to the surface. This is especially beneficial for fragile, soft, or easily deformed materials.

- Environmentally Friendly: Does not require the use of chemical solvents, reducing environmental pollution. It also produces less waste and noise compared to some traditional cleaning methods, making it more compliant with environmental protection requirements.

- Versatility: Can be used to clean a variety of materials and contaminants, including metals, plastics, ceramics, oxides, oils, rust, and coatings on their surfaces. Moreover, it can be easily adjusted to meet different cleaning requirements by changing the laser parameters.

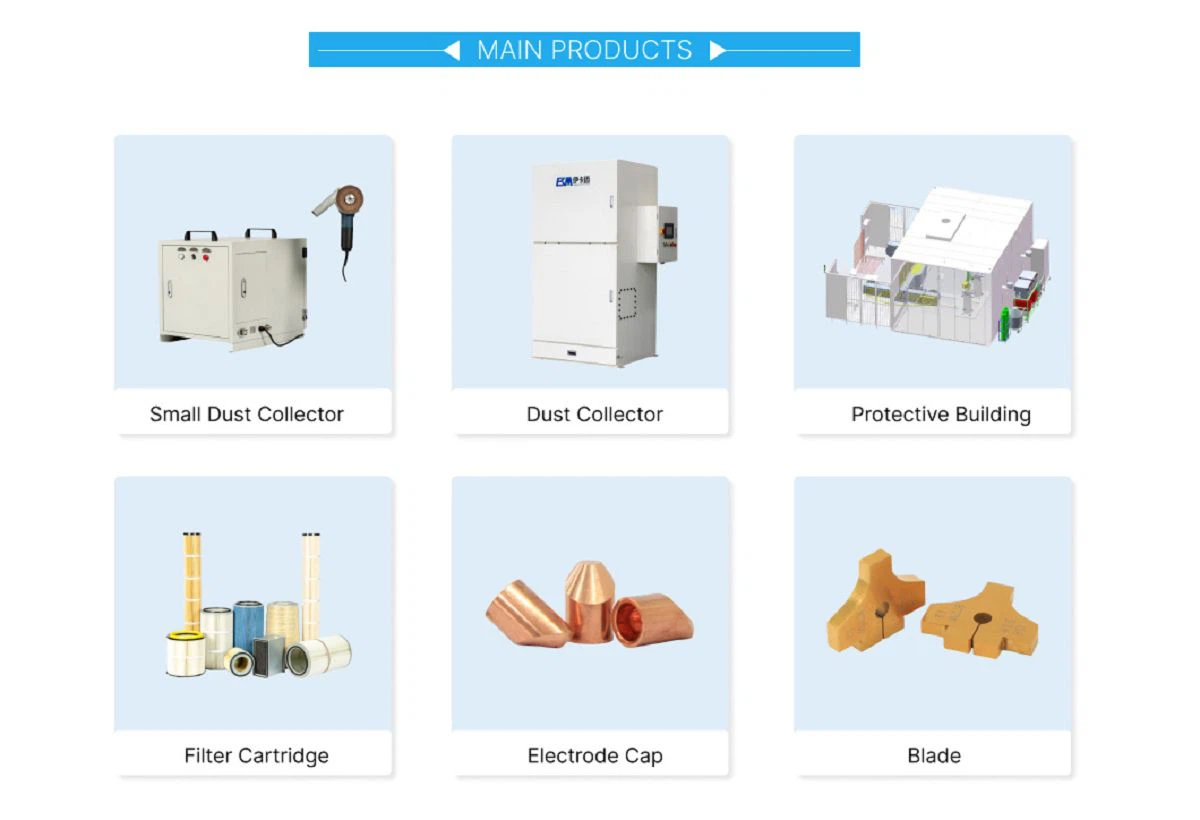

Hot Tags: Laser Decontaminator, China Laser Decontaminator manufacturers, suppliers, factory, dust collector, metal rust removal oxide painting coating removal laser cleaning machine, lcp 100whandheld cleaning laser, lcp a 100wcontinuous laser cleaning machine, welding fume extractor, lcc 2000w handheld cleaning laser